As you probably already know, economies of scale are cost reductions that occur when companies increase production. When you open an economics textbook and you read about it, you might find examples about company XYZ ordering 1 million units from their supplier instead of 100,000. I remember being a college student and learning about these economics concepts; it did not feel much different than learning about trigonometry in middle school: “When am I going to use this outside the classroom?” was my immediate thought.

As a small business, reading examples involving high numbers and huge industrial companies can be intimidating, leading you to think that economies of scale are something that large established companies should care about. However, even though the areas of improvement will differ between small businesses and larger companies, both can take advantage of the economies of scale.

Let’s go over a few types of internal economies of scale (those who have control within the company as opposed to external economies of scale where you have no control over), and how to exploit them as a small business to lower your costs and improve your bottom line.

Commercial economies of scale

This is usually the first thing that comes to people’s minds when they think of economies of scale. A company places a large order of products or raw materials and, in turn, is able to get a discount based on quantities ordered and – save on shipping costs, since shipping one large order is usually cheaper than shipping several small orders. Fortunately, commercial economies of scale don’t only apply to companies purchasing 50,000 tons of steel or 500,000 car seats. Think about it; when you go to the grocery store, you make economies of scale by buying a pack of 3 toothbrushes for $4.99 rather than a single one for $2.49. You might also save money on gas by making fewer trips to the store.

Small businesses are typically unable to purchase enough raw materials or inventory from their suppliers that they get the best quantity discounts available. Sometimes, they cannot even afford the MOQ (Minimum Order Quantity) their suppliers ask for. That is why many small businesses doing private labelling will work with a middleman or trading company that is able to fulfill smaller orders but charge a premium on the products.

The inability to get the best discounts makes it difficult for small businesses to compete solely on pricing against the largest contenders in the industry. As a small business, unless you have a unique business model or technology that allows you to drastically cut costs, focusing on pricing might not be the best idea. Most of the time, you’d be better off leaving the “Everyday Low Prices” to Walmart and having another plan.

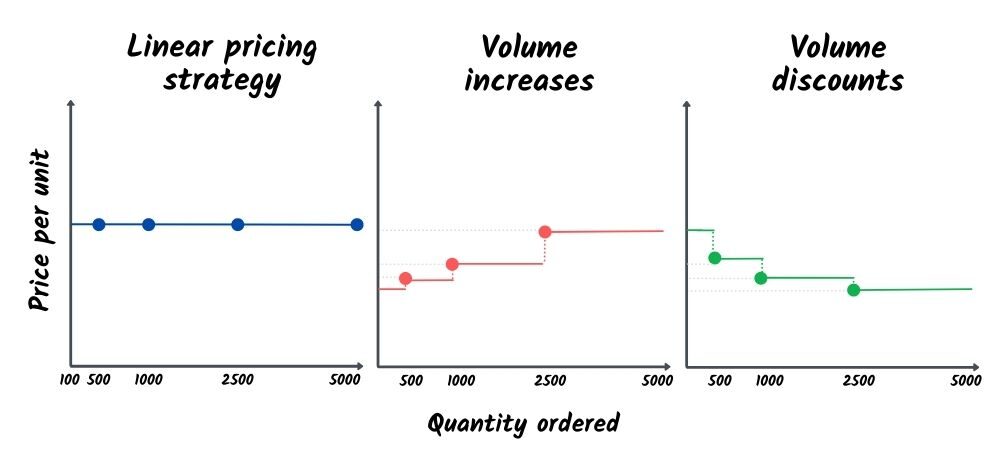

However, despite not being able to achieve the best possible discounts, smaller businesses can still take advantage of commercial economies of scale. First of all, selected suppliers use a linear pricing strategy and sell their products or materials at the same price, no matter how many units are ordered. Excluding other costs such as inbound logistics, a company placing a larger order will have no cost advantage over a competitor placing a smaller order. In a few other industries, prices increase with larger volumes of products ordered.

Yet, most of the time, suppliers provide volume discounts. By looking at the above price structure, you can notice something interesting. First, the discount given based on quantities ordered is not linear: the price per unit tends to converge towards a minimum price. Manufacturers need to make a profit and can’t drop their prices indefinitely. Then, there is the price break structure: the biggest price breaks occur first. After that, the more the buyer purchases, the smaller the price breaks get. Costs per unit are a lot higher for the smallest purchases due to the supplier’s high fixed costs, this then decreases as the order becomes larger. This allows smaller businesses to take advantage of these volume discounts, without being at a huge disadvantage compared to larger companies.

If that is not enough, you can always try to negotiate a solution with your supplier. For example, instead of placing one small order, signing a long-term contract for multiple orders can give you the leverage to get a better price per unit. Sure, it is a risky commitment, but it can help you achieve better pricing while protecting yourself from price increases and shortages. Placing consolidated orders with other companies in the industry can be another solution to decrease prices. Of course, you can’t form a purchase consortium to buy unique products for your brand, but for some standardized supplies, this could be a feasible idea.

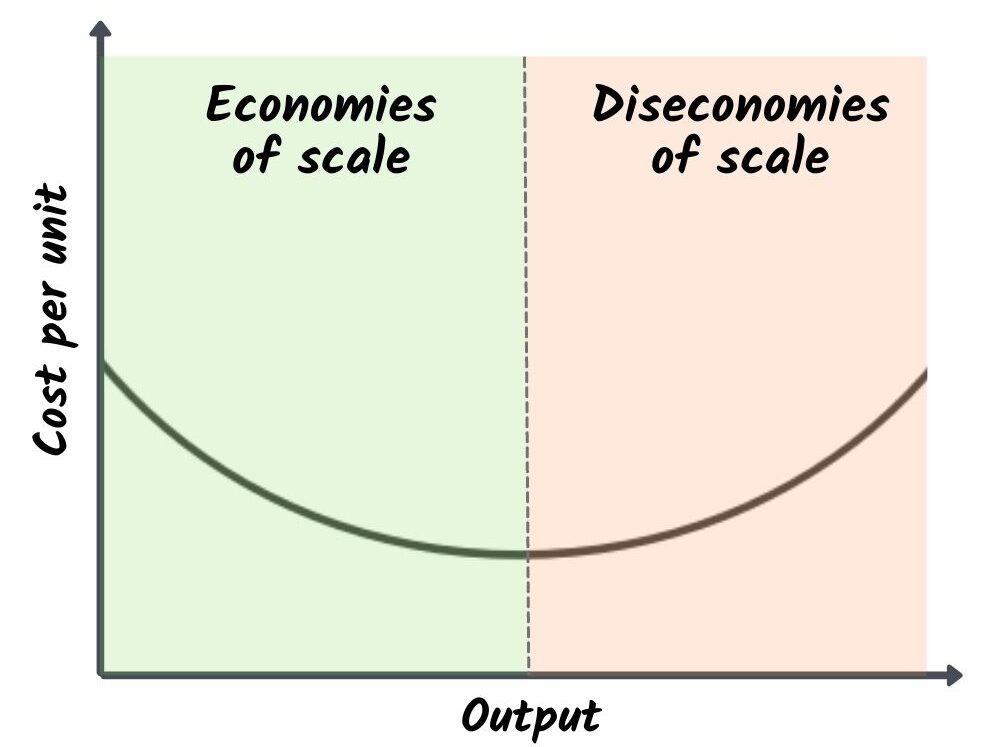

Finally, after a certain point, the cost per unit tends to increase and diseconomies of scales tend to occur. Diseconomies of scale can happen in many situations, including when trying to benefit from commercial economies of scale, and is one of the reasons that ordering as many units as possible isn’t always the most cost-effective solution. For example, if you order so many units that you run out of storage space in your warehouse, the warehouse will become a huge mess, making order processing and inventory management much more difficult and costly.

Technical economies of scale

Using advances in technology and process improvement is another way to generate economies of scale. There are many ways in which a small company can take advantage of technical economies of scale and invest to improve its profitability.

If you manufacture your own products, then cost improvement can be made beyond getting better prices on raw materials. Auditing your production processes can help you spot inefficiencies or redundant steps, and maybe even find ways to innovate. A major example is when Ford introduced the assembly line to mass-produce cars in 1913. Semi-finished cars moved from workstation to workstation, and parts were added until the product was finished. This helped lower the cost of the Model T from $850 in 1908 to $310 by 1926.

If you manufacture your own products, another way to lower costs per unit is to get better tools and machinery. Perhaps the investment is not worth it, and you might not need any state-of-the-art equipment if you don’t have huge production, but it can be interesting to explore your options. A landscaper might be better off buying high-end equipment that is more reliable and helps him work faster, rather than using a piece of junk that slows him down.

However, technological improvement does not only affect manufacturing processes. There are dozens of software that can help small businesses with tasks like order processing or inventory management. Of course, not every company needs a complex enterprise resource planning software like SAP, which costs thousands of dollars per user per year. But, using the right tools can help you save money. Upgrading from clunky Excel files to real software can make order processing a lot faster, limit the risk of errors, and lower your costs. As long as the cost does not outweigh the benefit, and does not overcomplicate your processes, this can be a good option.

Marketing economies of scale

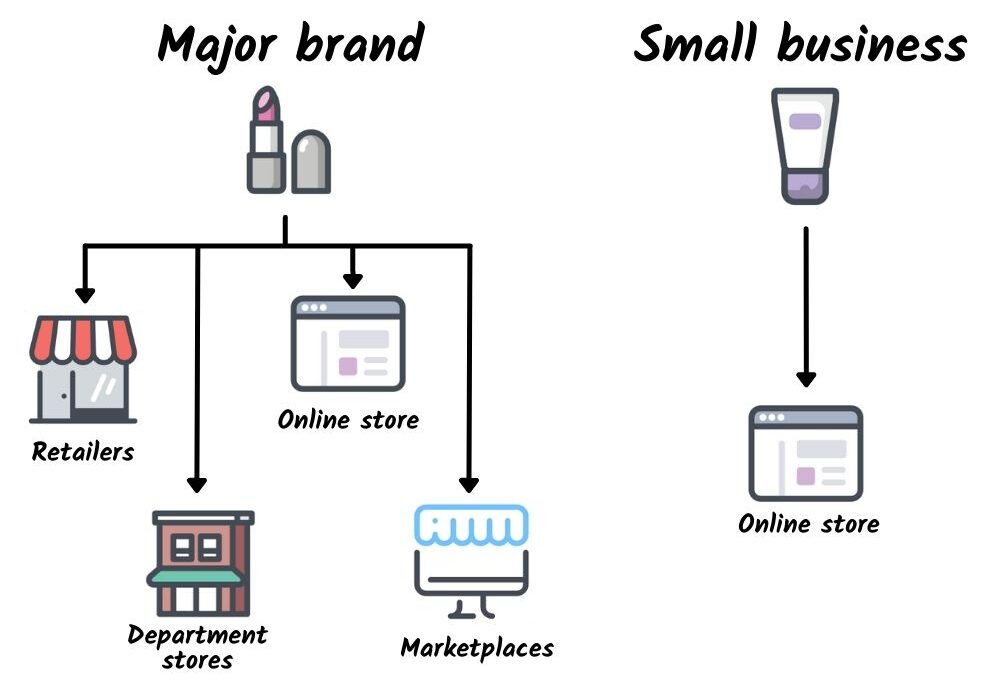

Marketing is a key part of many companies’ strategies, no matter their size. And the more a company grows, the more its marketing expenses tend to increase. However, the bigger a company is, the more they can spread their marketing expenses over larger volumes of sales. For example, let’s compare two businesses: a major brand of beauty products vs a small business selling natural and organic skincare products.

The large brand has its products on the shelves of hundreds of retailers and department stores, on their own website as well as other retailer websites, and several online marketplaces. The small business is only selling on their website.

If both companies spend thousands of dollars on a marketing campaign to generate brand awareness, the benefits of that campaign will be spread out over all their distribution channels. The major brand will reach many potential customers, including people shopping at retail and department stores, marketplaces, and those coming across the brand’s website. Now for the small business; customers will only be tempted to buy their products if they visit the brand’s website.

The major brand’s ad campaign may not be shown to more people if they spend the same amount as the small company, but a larger proportion of people coming across the ads will actually see the products online or on the shelves of physical stores. This will result in more sales, and the cost per unit sold will be much lower, resulting in economies of scale (not counting how people might already know and recognize a well-established brand). For the small company, building awareness ad campaigns won’t generate as many sales, and the cost of the campaign per unit sold will be high.

Knowing this trend, what can a small business do to save on marketing costs? One solution to begin with is to imitate the large businesses and sell your products on multiple channels. Not only can this lower your marketing costs per unit but it has many other benefits, such as limiting the risks should something go wrong with one channel. However, I think the key for small businesses with little brand awareness and low marketing budgets is to create laser-targeted marketing campaigns that focus on conversions. Not every company is the size of L’Oreal or Coca-Cola, and for a small business, imitating the giants will be extremely expensive and are very likely to fail.

Huge companies have massive marketing budgets and often focus on the long term. They spend millions just to show their products and brand to as many people as possible; through online ads, billboards, TV, social media, etc. They are doing it to make sure their brand is always in their target customers’ minds, to the point that people begin to wonder if advertisers make their ad annoying on purpose (these brands usually have a very broad target demographic). A small business does not have that same budget and should focus on making sales and growing its brand. That is why focusing on conversions is usually a better use of your marketing dollars (and is less likely to piss off your audience as much). Choosing the right channels, targeting the right demographic, writing quality copy, and using powerful call-to-actions will make your campaigns much more profitable and should help you generate sales.

In the next article, we’ll look at two other types of economies of scale: managerial and network.